Security control system

Shikoku Operations is reinforcing its own security system by creating a "security control system" in accordance with the High Pressure Gas Safety Act and establishing the Shikoku Operations' Policy.

Industrial safety and health management system

Shikoku Operations has established an industrial safety and health management system and is ISO45001 certified. We are working towards systemic and continuous industrial safety and health improvement by performing the PDCA (Plan > Do > Check > Action) cycle according to Shikoku Operations' Policy.

ISO45001 certification

| Certified Date | January 31, 2020 |

|---|---|

| Certification body | Certification body ISO Registration Center of the High Pressure Gas Safety Institute of Japan |

Safety management measures

Shikoku Operations assigns the highest priority to its safety management and posts the ″Declaration of Safety.″

The basic philosophy of the Declaration of Safety is the ″maintenance and continuation of zero accidents and disasters″ and is based on the philosophy of human dignity: ″Every individual is unique.″

With regard to daily business activities, the upgrading of the workplace environment follows the motto ″Stick to the basics, ’Check first’″ and is derived from the notion of preventive maintenance; at the same time, a movement to brighten the workplace and make it more cheerful is carried out through the TSC Movement and other business improvement activities.

TSC Movement

The TSC Movement, derived from the initial letters of Taiyo, Safety, and Check, is a “movement for the creation of a safety culture” involving all employees. The TSC Movement was launched in FY2003, with key issues established every three to five years. The sixth plan (five years long) was launched in FY2018, and is being carried out in a top-down manner. Furthermore, business continuation and improvement activities are being conducted by small group teams within each department in a bottom-up manner. The details of activities are reported at the TSC Movement Promotion Meeting held once a year.

| The TSC Movement implies as follows: | ||

|---|---|---|

| T | TAIYO | Taiyo Oil Co., Ltd. and its affiliated and collaborating companies. |

| S | SAFETY | Maintenance and continuation of [zero] accidents and disasters

|

| C | CHECK | Taiyo Safety Check Movement

|

|

CULTURE |

Creation of a safety culture (restructuring) | |

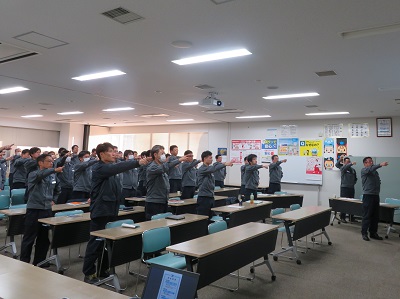

TSC Movement

-

Conference for the promotion

-

″pointing and calling″

-

Messages from the President

In-house comprehensive disaster-prevention activities

Shikoku Operations has established the self-disaster prevention department according to the Act on the Prevention of Disaster in Petroleum Industrial Complexes and Other Petroleum Facilities, and has also formed a joint disaster prevention department with neiboring business establishments for mutual aid and assistance. Further drills are planned to ensure disaster readiness on the part of emergency response units, as well as their disaster relief expertise. They are to be carried out regularly and cover all forms of disaster readiness.

In the comprehensive disaster drills held every year, more practical drills are carried out with the aim of strengthening cooperation with related organizations such as the Imabari Coast Guard Department and the Imabari City Fire Department and improving disaster response capabilities.

-

Fire trucks pumping water from the ocean via water supply hoses due to damaged outdoor water supply facilities

-

Fire trucks spraying water pumped from the ocean

-

Training for evacuation following a tsunami warning

-

Laying of iron plates accompanying road cave-ins

-

Oil fence extension by workboat

-

Antidisaster vessel preventing spilled oil from spreading